Hexagon AM Studio

Simplification of additive manufacturing.

AM STUDIO stands out as a state-of-the-art and user-friendly solution for additive manufacturing and provides end-to-end support in every stage of the production process, including post-processing.

Easily realize product design

Intuitive software guides you step by step through the 3D printing process—for optimized resource utilization, reduced training effort, and higher ROI.

Features:

- Part alignment

- Create support structures

- Positioning & nesting

- Define process parameters

- Simulation of mechanical stresses

- Slicing & hatching

- Generation of print files

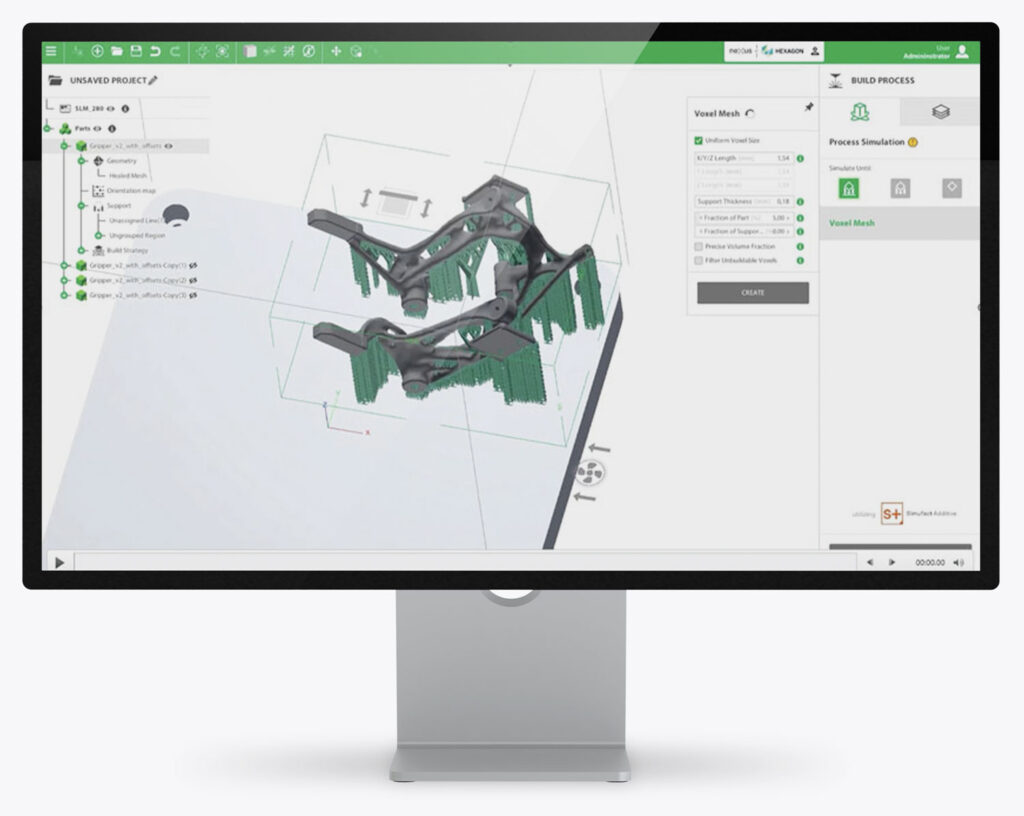

Intuitive user interface

AM STUDIO guides you through the entire 3D printing process – from import to post-processing.

With a graphical guide, intelligent algorithms, and automated workflows, additive manufacturing becomes simple and efficient.

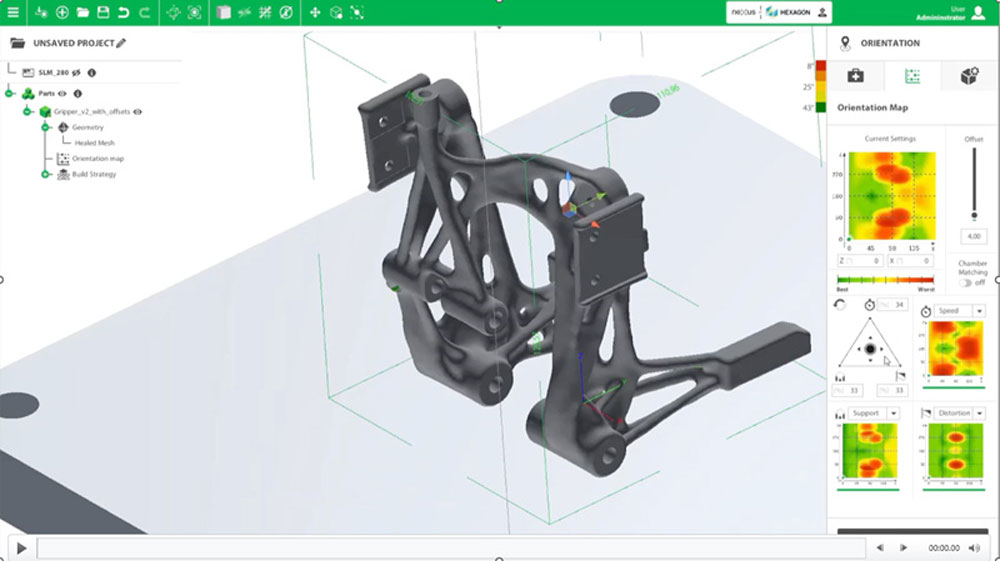

Optimal part alignment

Based on intelligent algorithms, so-called “OrientationMaps” support 3D nesting during data preparation. The arrangement of the parts is displayed in color-coded zones, highlighting both the optimal position and the orientation of the parts.

Advanced support geometries

In addition to standard support geometries, AM STUDIO also offers sophisticated, specialized support structures. With the help of artificial intelligence, users can save both build time and costs by drastically reducing the time to print.

Efficient segmentation

The integrated, powerful algorithms enable users to quickly generate and process segmentation data while keeping memory consumption low.

Cost estimation

AM STUDIO combines proven machine manufacturers’ algorithms for build time estimation with part and material data to create a high-quality estimation of build costs.

One software, multiple functions

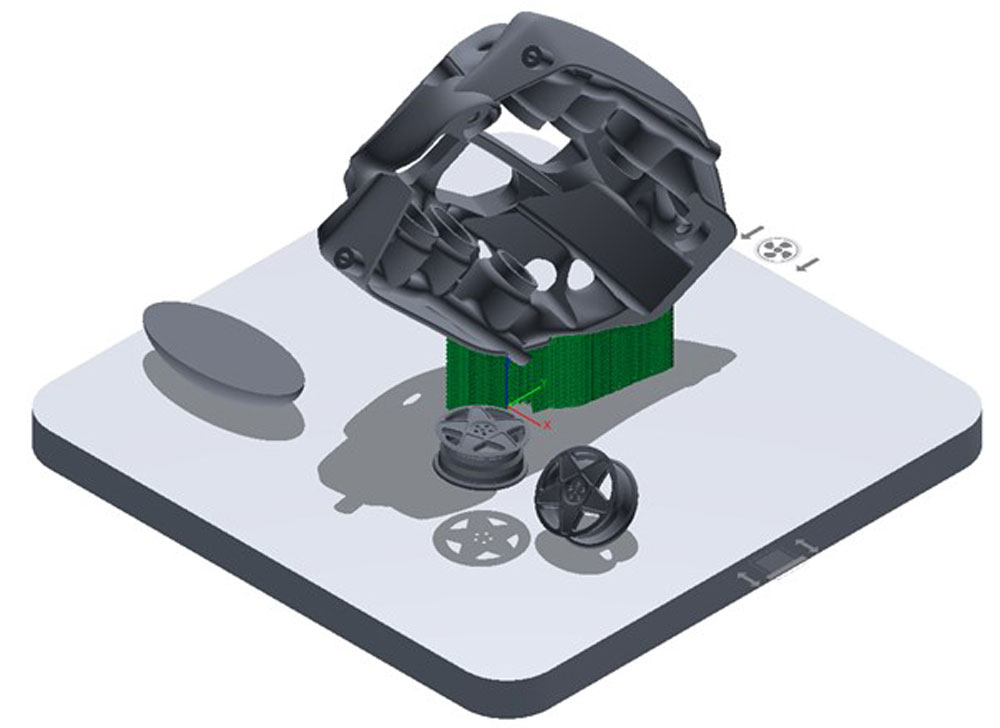

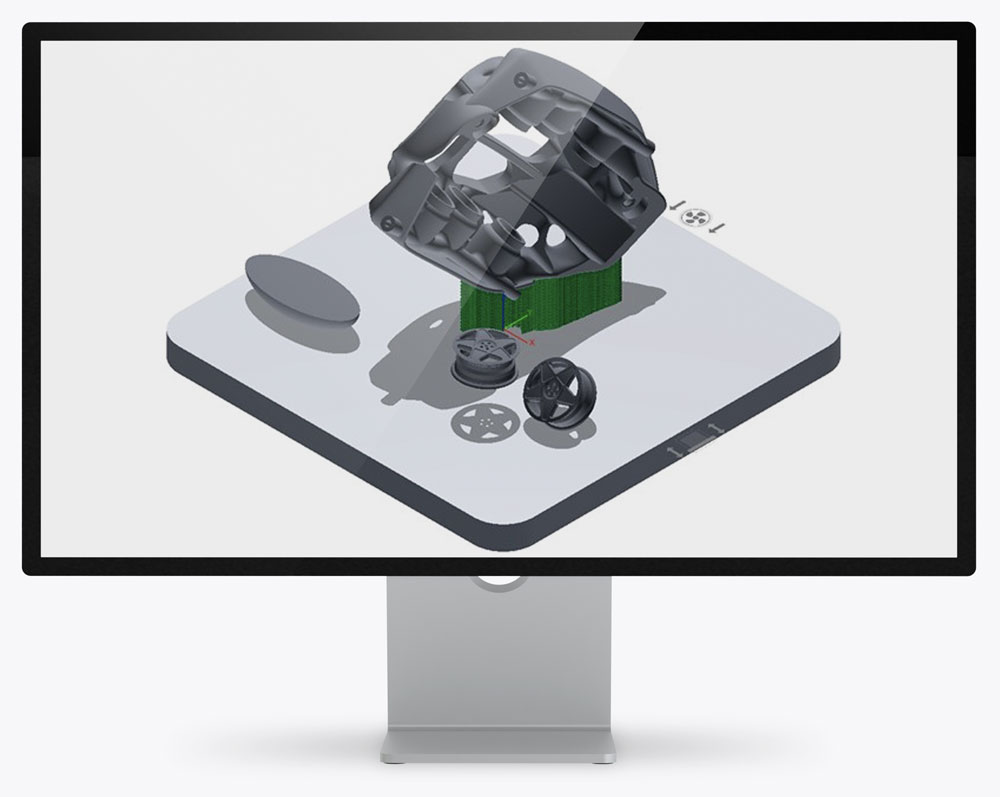

Advanced 3D view

The improved 3D view with object shadows in our update provides enhanced spatial perception, enabling precise object placement and orientation thanks to realistic shadow visualization and improved depth perception.

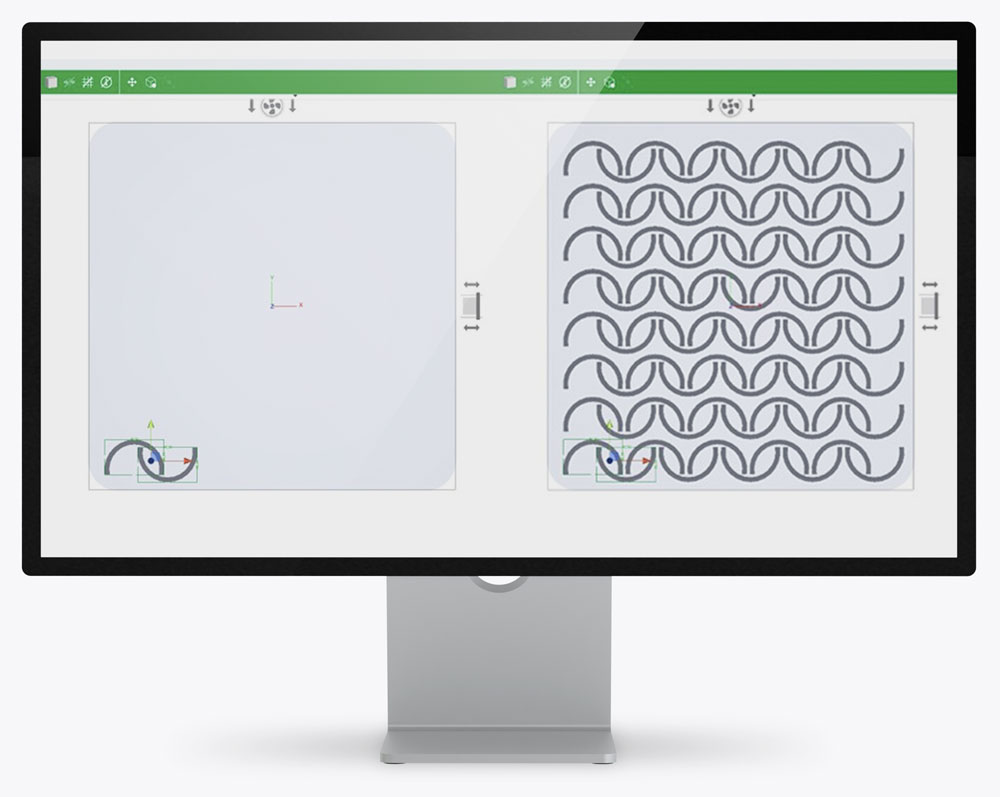

Nesting / Patterning

The new algorithm in our latest update allows users to define nested configurations of selected components as mandatory for patterning. It optimizes space utilization in the build area, minimizes waste, and maximizes productivity. Users can now create more complex and customized patterns, providing the flexibility to meet diverse manufacturing requirements.

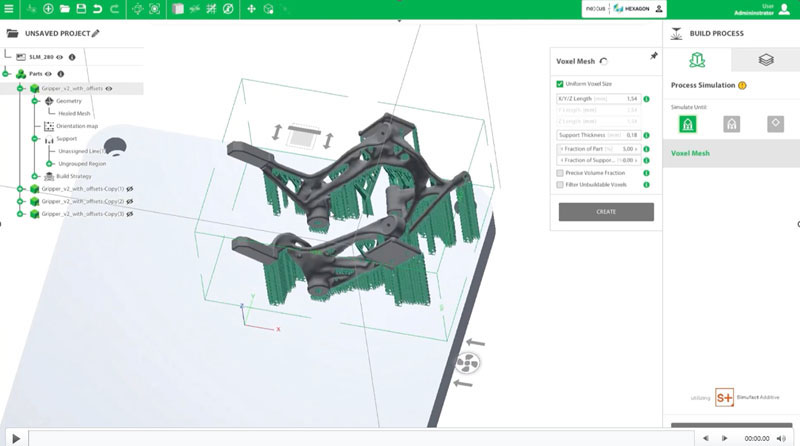

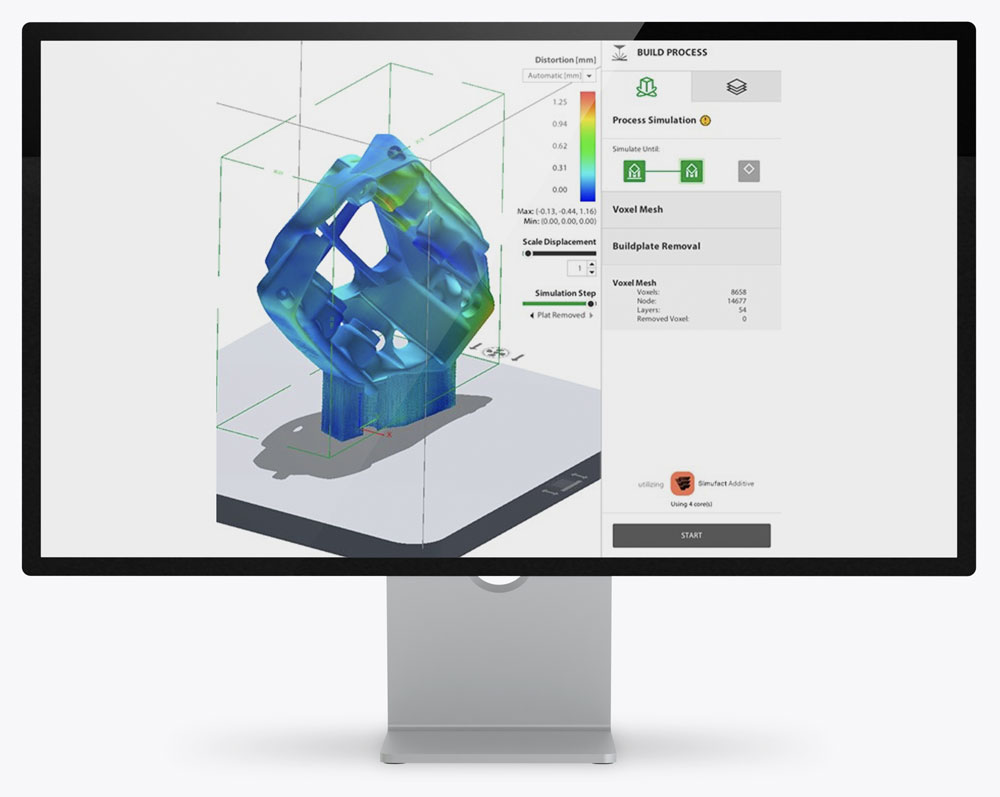

Simulation

Our latest update introduces multicore simulation and accelerates simulation runtimes by utilizing additional CPU cores (up to 4), thereby reducing calculation time for a faster and more efficient design process.

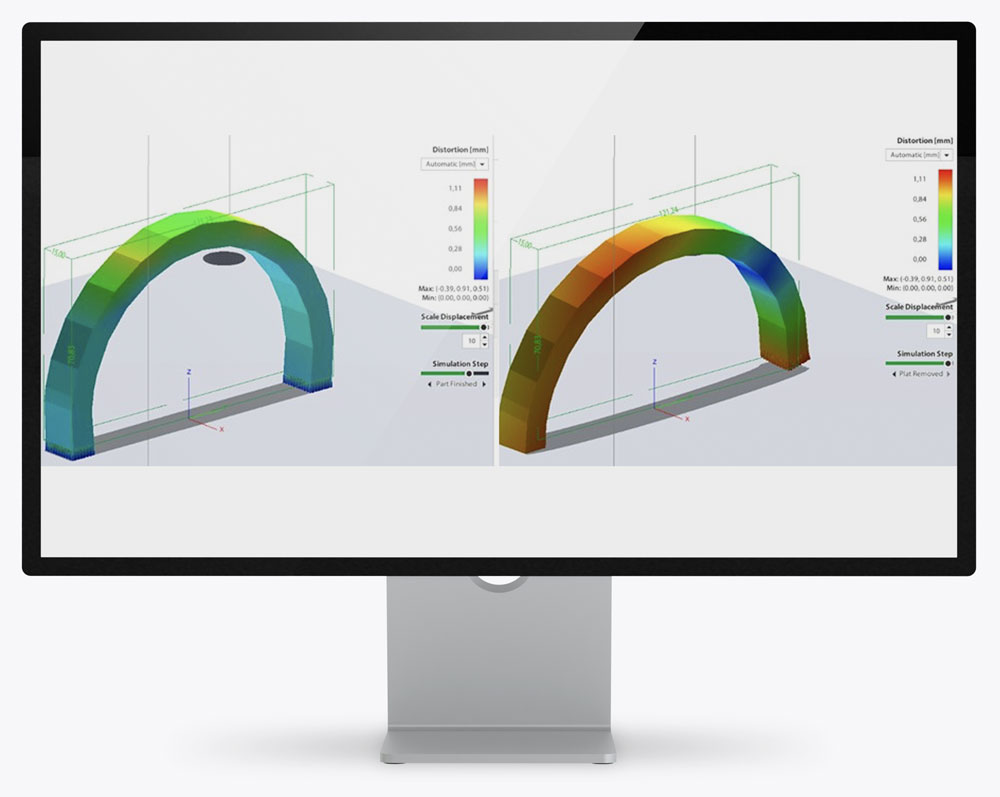

Deformation

Our new feature simulates the separation of a component from the build plate before heat treatment and enables users to anticipate and mitigate potential deformations caused by thermal stresses during the process, thereby improving the accuracy and integrity of their designs.

Downloads

Technical Specifications

| Mindestanforderungen Hardware | Windows 10, 64 Bit: Es werden ausschließlich professionelle Versionen unterstützt. Prozessor mit SSE2-Unterstützung: Alle 64-Bit-Prozessoren unterstützen SSE2. Die Grafikkarte unterstützt entweder OpenGL oder DirectX: Mindestauflösung 1920x1080. Mindestens 65.000 Farben. OpenGL-Grafikkarten müssen OpenGL 3.0 unterstützen. DirectX-Grafikkarten müssen DirectX 9.0c unterstützen. 4 GB RAM. |

| Empfohlene Hardwareanforderungen | Windows 10 Creator und später. Grafik: 512 MB+ integrierter RAM. ATI FirePro Serie oder die NVidia Quadro Serie inkl. neueste Treiber. 16 GB RAM. SSD Festplatte. |

| Empfohlene Hardwareanforderungen für Reverse Engineering und Datenerfassung | Windows 10 Pro, 64 Bit. 64GB RAM. Intel Xeon Prozessor @3 GHz oder gleichwertig. NVIDIA Quadro P5000 mit 5 GB Speicher. |