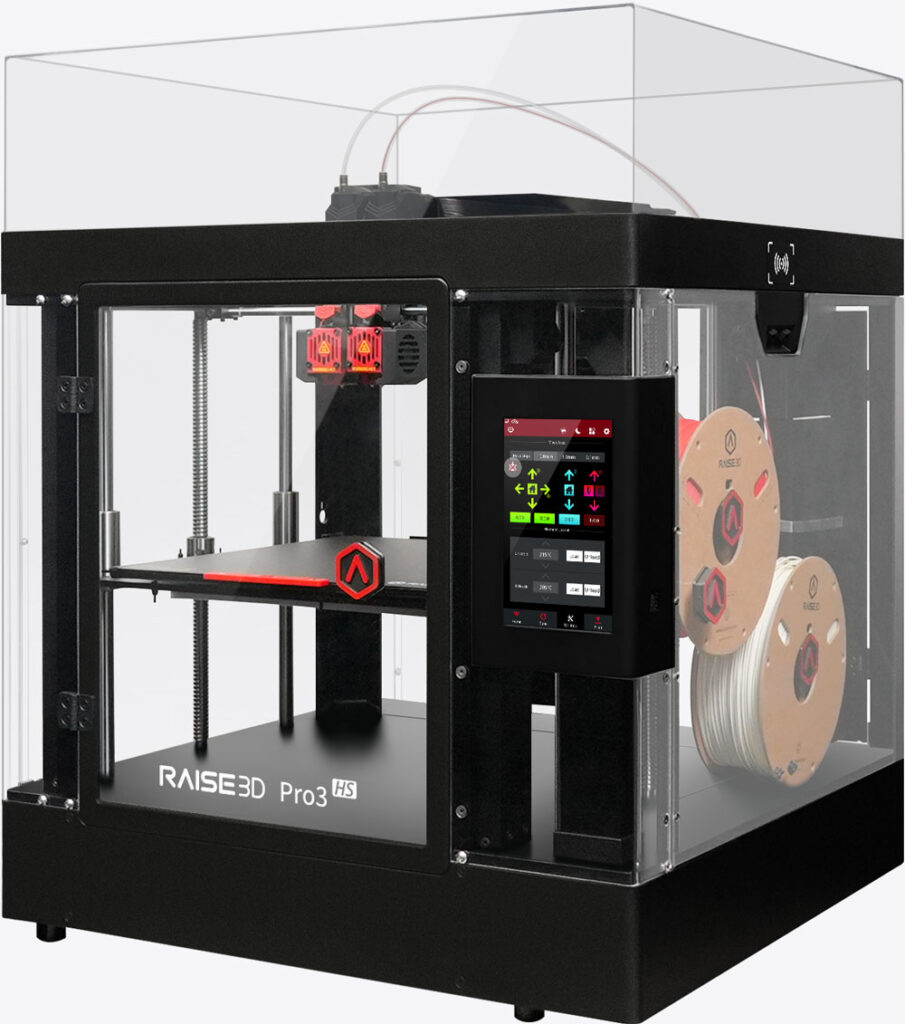

Raise 3D Pro3 HS

3D printing of large composite parts made easy.

The Raise3D Pro3 HS is a powerful professional-grade 3D printer based on the Pro3 Series, equipped with integrated Hyper FFF® technology. It offers leading speeds for printing composite materials with high efficiency and reliability. The enhanced motion control system with a closed-loop stepper motor further improves the precision and accuracy of high-speed printing, making it ideal for printing demanding industrial applications with minimal manual intervention.

Aerospace

Architecture

Automotive Industry

Commercial Good

Education

Medicine

Enhanced accuracy for industrial applications

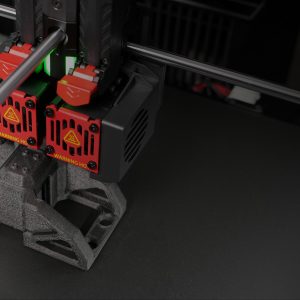

The Raise3D Pro3 HS Series integrates Hyper FFF® technology for precise and reliable high-speed printing, with Hyper Speed technology providing a high-flow hot end and an active vibration reduction algorithm. Capable of printing at 300 mm/s, the Pro3 HS Series is equipped with a closed-loop stepper motor in the motion control system, enhancing extruder motor movement control and enabling more precise high-speed printing. The new build plate provides uniform magnetic adhesion, reducing model warping. The optimized shaft ensures better sealing and motion stability, while the robust all-metal frame ensures smooth movement and precise positioning.

1,75 mm

Filament Diameter

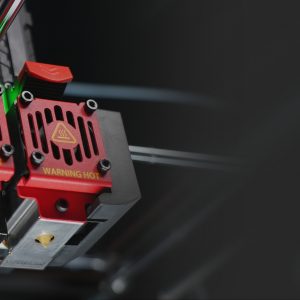

320°C

Extruder Temperature

300 mm/s

Print Speed

300 x 300 x 300 mm

Print Volume

Auto Bed Leveling

Auto bed leveling improves bed adhesion and allows the extruder to adjust to even the most minor of surface contour changes for better final print quality.

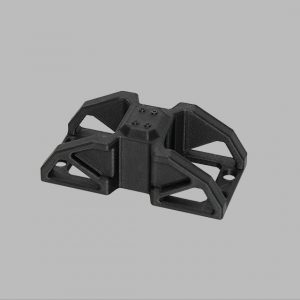

Flexible Build Plate

The flexible build plate can be bent to easily remove 3D printed parts while minimizing potential damage to the final print. The Pro3 HS Series is also compatible with metal build plate, and high temperature build plate made of 100% pure borosilicate glass.

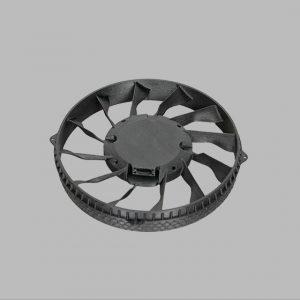

Air Flow Manager

The Air Flow Manager of the Pro3 HS Series improves heat dissipation and air circulation, and creates a stable environment inside the print chamber. Equipped with a HEPA air filter, Air Flow Manager can also filter and clean the air inside the chamber.

HEPA Air Filter

The Pro3 HS Series uses HEPA air filtration to clean the air of any particles (incl. nano-particles) released during the 3D printing process. The HEPA air operates silently, quietly working in the background of any work area.

Lightweight Cable with Digital Temperature Measurement

The Pro3 HS Series replaces the drag chain cable with a lightweight cable, to reduce the weight of the extruder and keep the center of gravity in the middle during printing for more stable print quality. The Pro3 Series also uses digital temperature measurement, for accurate and anti-jamming temperature reading.

EVE Smart Assistant

The EVE assistant can guide users to accurately locate and resolve issues that could affect the final print job. It has a function that gives users reminders about regular scheduled interventions to ensure that printer maintenance is performed on time. It also helps reduce maintenance time and communication costs for an efficient maintenance process.

Raise 3D Pro3 HS Webinar

To help you get up and running with your new 3D printer quickly, we offer you our quick start course in the form of a webinar (web-based seminar): After 120 minutes, you will understand how to use the 3D printing software.

Webinar Agenda

- Introduction to the functionality and operation of the 3D printing software

- Overview of the importance of settings

- The right settings for your perfect 3D print!

- Tips & Tricks

- Troubleshooting – Causes and solutions for common problems

Requirements

- Existing, ready-to-use PC with Windows 7, 8, or Mac OS X with full administrator rights

- Internet access

- Pre-installed and functional TeamViewer or Microsoft Teams software

The details of the appointment and the webinar software will be arranged after receiving your order.

Support and Service

- Professional consulting

- Sample print creation

- Custom packages for industrial clients

- On-site training

- Service package with free phone and email support

- Complete solution with wash station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Downloads

Technical Specifications

| Typ | Fertiggerät |

| Technologie | FFF (Fused Filament Fabrication) |

| Bauvolumen (B×T×H): – Einzel-Extrusionsdruck | 300 × 300 × 300 mm |

| Bauvolumen (B×T×H): – Dual-Extrusionsdruck | 255 × 300 × 300 mm |

| Maschinengröße (B×T×H) | 620 × 626 × 760 mm |

| Druckkopf | Doppelkopf mit elektronischem Hubsystem |

| Filamentdurchmesser | 1,75 mm |

| XY Schrittweite | 0,78125 Mikron |

| Z Schrittweite | 0,078125 Mikron |

| Verfahrgeschwindigkeit des Druckkopfes | 300 mm/s |

| Bauplatte | Flexible Stahlplatte mit BuildTak |

| Maximale Temperatur der Platte | 120 ºC |

| Beheiztes Bettmaterial | Silikon |

| Build Plate Leveling | Mesh-leveling with Flatness Detection |

| Filament Run-out Sensor | Available |

| Unterstützte Materialien | PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glasfasergefüllt / Kohlefaserverstärkt / Metallpartikel gefüllt / Holzgefüllt |

| Layer Height | 0.05 – 0.6mm |

| Düsendurchmesser | 0.1 – 0.3 mm |

| Maximale Düsentemperatur | 320 ºC |

| Konnektivität | Wi-Fi, LAN, USB-Anschluss, Live-Kamera |

| Geräuschemission (Schall) | < 55 dB(A) beim Bauen |

| Betriebsumgebungstemperatur | 15-30 ºC, 10-90% RH nicht kondensierend |

| Lagertemperatur | -25ºC bis +55ºC, 10-90% RH nicht kondensierend |

| Netzteileingang | 100-240V AC, 50/60Hz 230V @3.3A |

| Filter | HEPA filter with activated charcoal |

| EVE Smart Assistant | Available |

| Slicing-Software | ideaMaker |

| Unterstützte Dateitypen | STL, OBJ, 3MF, OLTP |

| Unterstütztes Betriebssystem | WINDOWS/ macOS/ LINUX |

| Maschinencode Typ | GCODE |

| Benutzeroberfläche | 7 Zoll Touchscreen |

| Netzwerk | Wi-Fi, Ethernet |

| Power Loss Recovery | Available |

| Bildschirmauflösung | 1024*600 |

| Motion Controller | Atmel ARM Cortex-M4 120MHz FPU |

| Logiksteuerung | NXP ARM Cortex-A9 Quad 1 GHz |

| Speicher | 1GB |

| Onboard-Flash | 16GB |

| Betriebssystem | Embedded Linux |

| Ports | Usb 2.0*2, Ethernet*1 |