Creatbot PEEK 300

High-performance 3D printing for industrial and medical applications.

The PEEK-300 is engineered for extremely demanding polymer materials, combining a 480 °C nozzle temperature, a 200 °C heated bed, a 120 °C heated chamber, and a patented Direct Annealing System (DAS) – delivering flawless parts without warping, cracking, or post-processing.

Aerospace

Architecture

Automotive Industry

Commercial Good

Education

Medicine

Direct annealing – during the printing process.

The patented DAS system is unique worldwide: the annealing process takes place during printing itself and acts on every single extrusion line. This results in extremely strong, warp-free parts made from engineering, high-temperature and ultra-high-performance polymers – without an oven, without a second processing stage and without any risk of deformation. The ambient temperature can be precisely controlled from 0 to 200 °C, allowing toughness and material properties to be optimally adjusted.

1,25 µm

Positioning accuracy (Z-axis)

Up to 480°C

Extruder Temperature

Up to 180 mm/s

Print Speed

300 x 300 x 400 mm

Print Volume

480 °C dual extruder with water cooling

The intelligent auto-rising dual extruders reach up to 480 °C and enable printing of all high-performance materials – from PEI (ULTEM) to PEEK-CF. With water cooling, the DAS system and direct drive, they ensure maximum stability and material control.

Heated bed up to 200 °C & 120 °C chamber

The thermal system is engineered for extreme requirements: a 200 °C heated bed, a 120 °C high-temperature chamber, and triple thermal insulation ensure warp-free large parts and optimal crystallization for PEEK, PEKK and other high-temperature polymers.

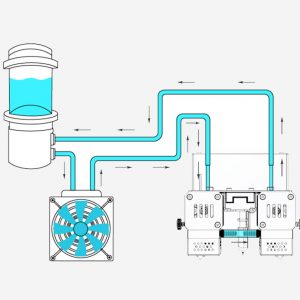

Advanced cooling system

Liquid cooling and air-pump cooling form a combined system for stable long-duration printing. Cool external air prevents heat buildup inside the chamber and improves print quality, surface finish, and layer adhesion when working with demanding materials.

Comprehensive material compatibility

From standard plastics to engineering polymers and ultra-high-performance materials: PLA, ABS, PC, PA6, PETG, PPSU, PEI, PA-CF, medical PEEK, PEKK, PEEK-CF and PEEK-GF – the PEEK-300 covers the full spectrum and enables industrial applications without limitations.

Ultra-performance 3D printer.

Precision, stability, and high-temperature performance for the most demanding applications.

With a build volume of 300 × 300 × 400 mm, a full-metal construction, automatic leveling, and a positioning accuracy of up to 0.00125 mm on the Z-axis, the PEEK-300 is engineered for the most demanding industries. High-temperature motors, precise linear guides, and a PEI-coated platform ensure industrial reliability. Whether functional PEEK components, validation-critical medical parts, or elements for high-temperature applications – the PEEK-300 delivers a level of quality typically found only in specialized manufacturing environments.

Creatbot PEEK 300 Webinar

To help you get up and running with your new 3D printer quickly, we offer you our quick start course in the form of a webinar (web-based seminar): After 120 minutes, you will understand how to use the 3D printing software.

Webinar Agenda

- Introduction to the functionality and operation of the 3D printing software

- Overview of the importance of settings

- The right settings for your perfect 3D print!

- Tips & Tricks

- Troubleshooting – Causes and solutions for common problems

Requirements

- Existing, ready-to-use PC with Windows 7, 8, or Mac OS X with full administrator rights

- Internet access

- Pre-installed and functional TeamViewer or Microsoft Teams software

The details of the appointment and the webinar software will be arranged after receiving your order.

Support and Service

- Professional consulting

- Sample print creation

- Custom packages for industrial clients

- On-site training

- Service package with free phone and email support

- Complete solution with wash station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Downloads

Technical Specifications

| Bauraum | Einzel-Extrusion: 300 × 300 × 400 mm Doppel-Extrusion: 240 × 300 × 400 mm |

| Filamentdurchmesser | 1.75 mm |

| Anzahl der Düsen | Dual Extruder |

| Düsendurchmesser | 0.4 mm (0.3–1.0 mm optional) |

| Filamentkompatibilität | Technische Kunststoffe: PLA, ABS, ASA, PC, Nylon, PETG, PVDF, Carbon Fiber Hochtemperaturmaterialien: UltraPA, UltraPA-GF, UltraPA-CF, PPSU, PEI (ULTEM) Ultrahochleistungsmaterialien: PEEK, CF-PEEK, GF-PEEK, PEKK etc. |

| Optimale Druckgeschwindigkeit | 55 mm/s |

| Maximale Druckgeschwindigkeit | 180 mm/s |

| Max. Düsentemperatur | 480 °C |

| Kammertemperatur | 120 °C |

| Max. Plattformtemperatur | 200 °C |

| Direkte Glühtemperatur (DAS) | 0–400 °C |

| Kühlung | Luftpumpenkühlung & Wasserkühlung |

| Plattform | Aluminiumplattform mit PEI-Beschichtung |

| Positioniergenauigkeit | X/Y: 0.0127 mmZ: 0.00125 mm |

| Extruder | Direktantriebsextruder |

| Maschinenkonstruktion | Vollmetallkonstruktion |

| Druckbett-Nivellierung | Automatische Druckbett-Nivellierung |

| Stromausfall-Wiederherstellung | Speichert Daten bei Stromausfall |

| Filamenterkennung | Pausiert den Druck bei Filamentende |

| Direktes Glühsystem (DAS) | Glüht während des Drucks; verhindert Verzug und Risse bei funktionalen Hochleistungsmaterialien |

| Wärmeisolierung | Dreifache Wärmeisolierung |

| Not-Aus-Schalter | Unterstützt |

| Hochtemperatur-Zubehör | Hitzebeständige Motoren, Linearschienen, Riemen und Schaltkreise für langanhaltendes Hochtemperaturdrucken |

| Bauraum | Einzel-Extrusion: 300 × 300 × 400 mm Doppel-Extrusion: 240 × 300 × 400 mm |

| Filamentdurchmesser | 1.75 mm |

| Anzahl der Düsen | Dual Extruder |

| Düsendurchmesser | 0.4 mm (0.3–1.0 mm optional) |

| Filamentkompatibilität | Technische Kunststoffe: PLA, ABS, ASA, PC, Nylon, PETG, PVDF, Carbon Fiber Hochtemperaturmaterialien: UltraPA, UltraPA-GF, UltraPA-CF, PPSU, PEI (ULTEM) Ultrahochleistungsmaterialien: PEEK, CF-PEEK, GF-PEEK, PEKK etc. |

| Optimale Druckgeschwindigkeit | 55 mm/s |

| Maximale Druckgeschwindigkeit | 180 mm/s |

| Max. Düsentemperatur | 480 °C |

| Kammertemperatur | 120 °C |

| Max. Plattformtemperatur | 200 °C |

| Direkte Glühtemperatur (DAS) | 0–400 °C |

| Kühlung | Luftpumpenkühlung & Wasserkühlung |

| Plattform | Aluminiumplattform mit PEI-Beschichtung |

| Positioniergenauigkeit | X/Y: 0.0127 mmZ: 0.00125 mm |

| Extruder | Direktantriebsextruder |

| Maschinenkonstruktion | Vollmetallkonstruktion |

| Druckbett-Nivellierung | Automatische Druckbett-Nivellierung |

| Stromausfall-Wiederherstellung | Speichert Daten bei Stromausfall |

| Filamenterkennung | Pausiert den Druck bei Filamentende |

| Direktes Glühsystem (DAS) | Glüht während des Drucks; verhindert Verzug und Risse bei funktionalen Hochleistungsmaterialien |

| Wärmeisolierung | Dreifache Wärmeisolierung |

| Not-Aus-Schalter | Unterstützt |

| Hochtemperatur-Zubehör | Hitzebeständige Motoren, Linearschienen, Riemen und Schaltkreise für langanhaltendes Hochtemperaturdrucken |