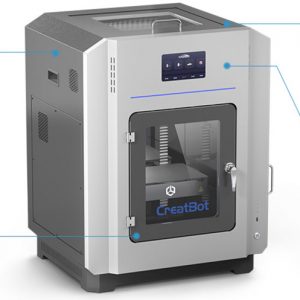

Creatbot PEEK 250

Desktop 3D printer with a true 200 °C heated chamber.

With a 480 °C extruder, a 200 °C build platform, and the world’s first true 200 °C high-temperature chamber, the PEEK-250 sets new standards in desktop high-temperature 3D printing – safe, stable, and process-oriented.

Aerospace

Architecture

Automotive Industry

Commercial Good

Education

Medicine

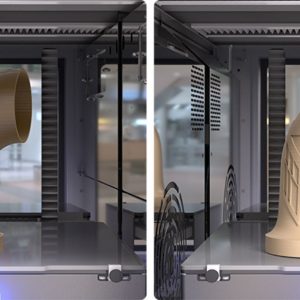

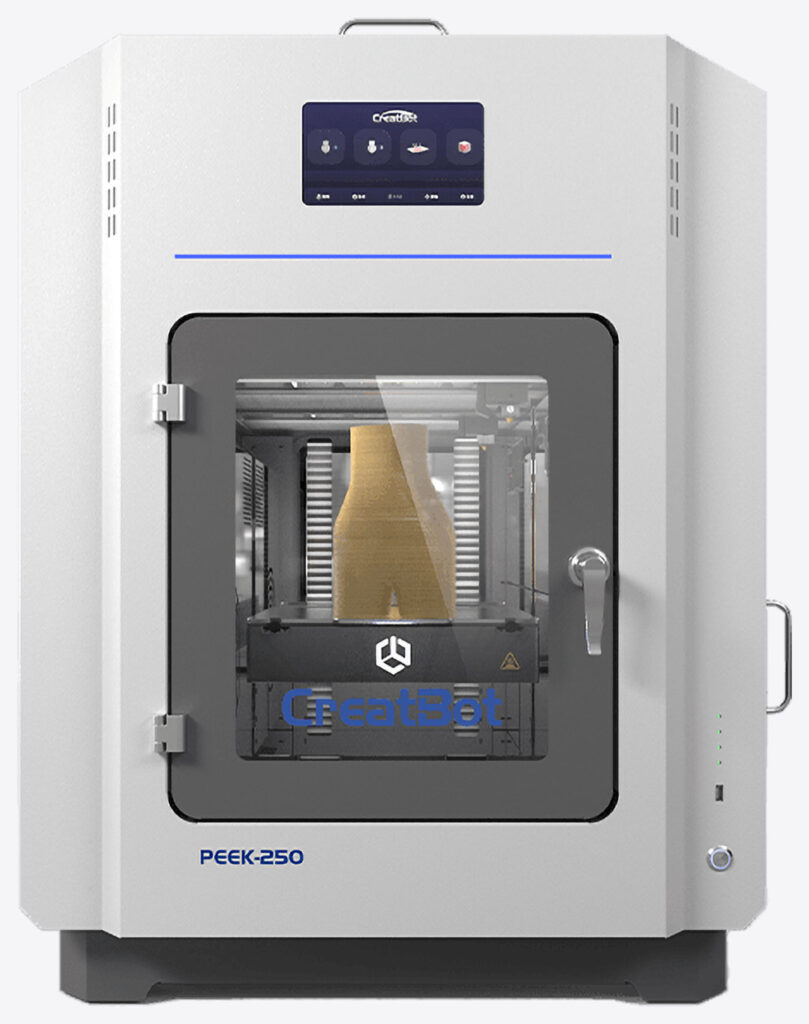

World’s first 200 °C desktop high-temperature chamber.

The PEEK-250 is the first desktop printer to achieve a fully usable 200 °C hot chamber. The temperature reaches 180 °C in just 20 minutes – perfect for PEEK printing and in-machine annealing. Models don’t need to be removed, moved or cooled in between. The triple-layer insulation ensures the exterior temperature stays below 40 °C even after 5 hours. Ideal for PEEK, PEI and all materials that require crystalline phase development and high ambient temperatures.

1,25 µm

Positioning accuracy (Z-axis)

Up to 480°C

Extruder Temperature

Up to 180 mm/s

Print Speed

250 x 250 x 300 mm

Print Volume

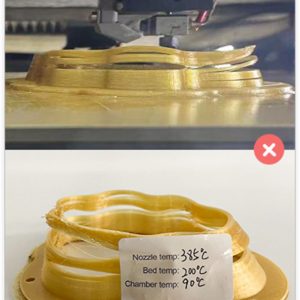

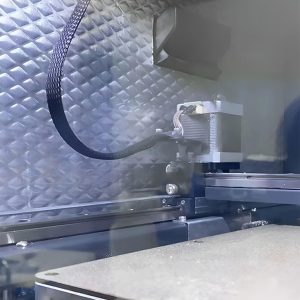

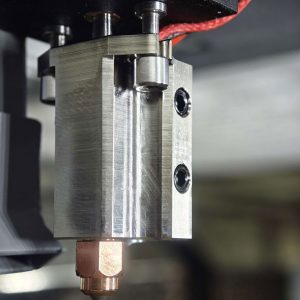

480 °C extruder system with water cooling

The dual-tooth silicon carbide extruder is designed for extreme continuous temperatures, water-cooled, and can be replaced within 30 seconds. It ensures maximum process stability when printing PEEK, PEI, UltraPA-CF, or other high-performance materials.

200 °C high-temperature chamber

The fully enclosed 200 °C chamber provides 360° hot-air circulation, prevents internal stress and enables warp-free parts. Perfect for printing and direct annealing of PEEK and PEI components.

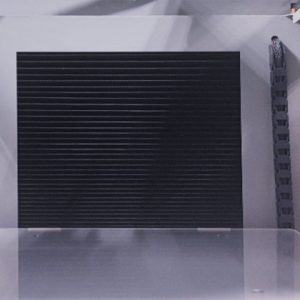

High-temperature build platform (200 °C)

The ultra-flat platform made of aerospace-grade aluminum with a polymer-coated printing surface remains level despite the extreme chamber environment (0.05 mm / 0.1 mm). No manual or automatic leveling is required.

One-step annealing function

PEEK and PEI models can be annealed directly inside the machine after printing. No removal, no cooling, no oven post-processing – a fully integrated high-temperature workflow.

High-temperature printing at an industrial level.

Safe, stable and built for extreme material requirements.

With a build volume of 250 × 250 × 300 mm, a fully enclosed heated chamber, air and water cooling, direct extruder drive and heat-resistant components, the PEEK-250 is a professional system designed for demanding polymer processing. Active door cooling, aerospace-grade insulation and high-precision mechanics enable a chamber temperature of 180–200 °C without heating the exterior – ideal for functional PEEK parts, PEI structural components and industrial high-temperature applications.

Creatbot PEEK 250 Webinar

To help you get up and running with your new 3D printer quickly, we offer you our quick start course in the form of a webinar (web-based seminar): After 120 minutes, you will understand how to use the 3D printing software.

Webinar Agenda

- Introduction to the functionality and operation of the 3D printing software

- Overview of the importance of settings

- The right settings for your perfect 3D print!

- Tips & Tricks

- Troubleshooting – Causes and solutions for common problems

Requirements

- Existing, ready-to-use PC with Windows 7, 8, or Mac OS X with full administrator rights

- Internet access

- Pre-installed and functional TeamViewer or Microsoft Teams software

The details of the appointment and the webinar software will be arranged after receiving your order.

Support and Service

- Professional consulting

- Sample print creation

- Custom packages for industrial clients

- On-site training

- Service package with free phone and email support

- Complete solution with wash station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Downloads

Technical Specifications

| Bauraum | 250 × 250 × 300 mm |

| Filamentdurchmesser | 1.75 mm |

| Anzahl der Düsen | Einzelner Extruder |

| Düsendurchmesser | 0.4 mm (0.6 mm optional) |

| Filamentkompatibilität | Technische Kunststoffe: PLA, ABS, ASA, PC, Nylon, PETG, PVDF, Carbon Fiber Hochtemperaturmaterialien: PET-CF, PET-GF, UltraPA, UltraPA-GF, UltraPA-CF, PPS UUltrahochleistungsmaterialien: PEI (ULTEM™ Full line), PEEK, PEEK-CF, PEEK-GF, PEKK etc. |

| Optimale Druckgeschwindigkeit | 55 mm/s |

| Max. Druckgeschwindigkeit | 180 mm/s |

| Max. Düsentemperatur | 480 °C |

| Kammertemperatur | 200 °C |

| Max. Plattformtemperatur | 200 °C |

| Kühlung | Luft- & Wasserkühlung |

| Druckplattform | PCB-Aluminium + PEEK-Druckplatte |

| Positioniergenauigkeit | X/Y: 0.0127 mm Z: 0.00125 mm |

| Extruder | Direktantrieb |

| Maschinenaufbau | Vollständig geschlossene Heizkammer |

| Stromausfall-Wiederherstellung | Daten werden bei Stromausfall gespeichert |

| Filamenterkennung | Druck pausiert bei Filamentende |

| Wärmedämmung | Dreischichtige Isolierung + aktive Luftkühlung (Kammertemperatur bis 180 °C, Außentemp. < 40 °C) |

| Hitzebeständige Komponenten | Motoren, Linearschienen, Riemen und Schaltungen für dauerhaftes Hochtemperaturdrucken |

| Türkühlung | Aktive Luftkühlung |