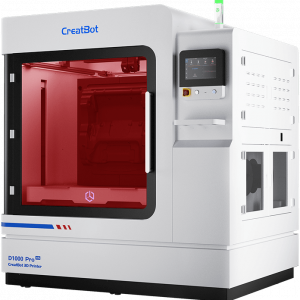

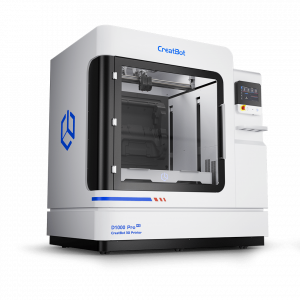

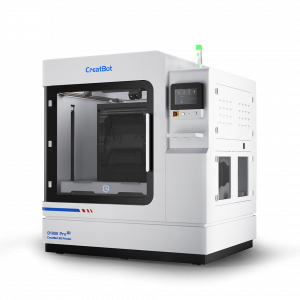

Creatbot D1000 Pro HS

Developed for large-format industrial manufacturing.

Industrial-grade 1-cubic-meter smart high-speed 3D printer for full-scale components, tools, and functional prototypes. With AI-assisted calibration, an automatic dual-nozzle system, an 80 °C heated industrial chamber, and a massive steel monocoque construction, it delivers reproducible industrial quality — reliably in 24/7 operation.

Aerospace

Architecture

Automotive Industry

Commercial Good

Education

Medicine

Industrial speed meets precision in large format.

The D1000 Pro HS combines a 90 mm³/s flow rate, reinforced linear rails, servo motors, an automatic nozzle shut-off, and AI-assisted sensor technology. Even on 1-meter axes, motion remains stable, precise, and low in vibration.

0,05 mm

Layer resolution

Up to 420°C

Extruder Temperature

Up to 300 mm/s

Print Speed

1.050 x 1.050 x 1.050 mm

Print Volume

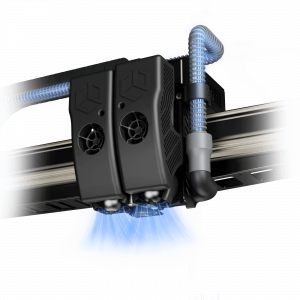

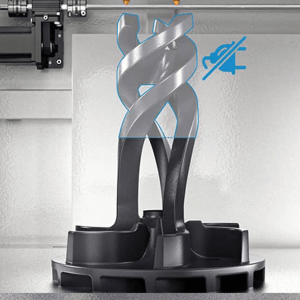

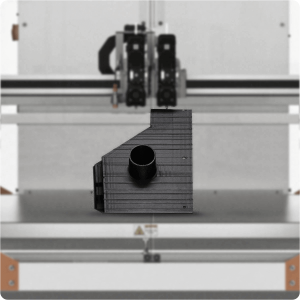

Automatically lifting dual extruders with nozzle shut-off (420 °C)

Intelligent dual-extruder system with a mechanical shut-off for the inactive nozzle. Prevents material leakage, cross-contamination, and stringing — essential for precise multi-material and support-structure printing. Fast nozzle changes, heating up to 400 °C in approximately 2 minutes, and temperature stability of ±0.15 °C. Ideal for ABS, PC, Nylon, PA-CF, and high-performance composites.

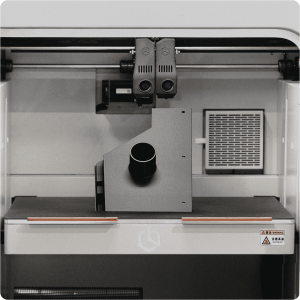

AI-assisted fully automatic calibration

HD macro camera for XY offset, electro-optical sensors for Z calibration, and eddy current bed scanning with 0.001 mm precision. Contactless platform calibration in just 60 seconds — a perfect first layer even on oversized build plates.

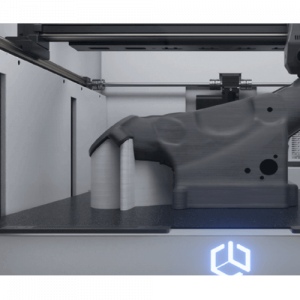

Actively heated industrial chamber (80 °C)

A double-layer insulation system maintains a constant 80 °C. Reduces thermal stress, prevents warping and delamination, and improves layer adhesion — essential for engineering plastics such as ABS, PC, or PA-CF.

Steel monocoque structure & servo drive

The precision-engineered steel monocoque construction minimizes vibration. Reinforced linear rails and servo motors ensure dimensional accuracy, smooth motion, and reliable industrial quality for meter-scale components.

Independent quad Z-axis

Four motors automatically level each corner of the platform. Ensures extreme parallelism, a perfect first layer, and consistent layer quality in large-format printing.

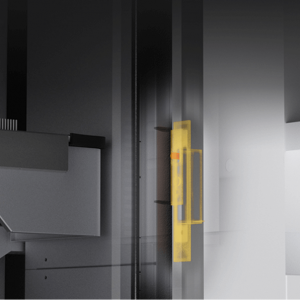

Safety & process continuity

The safety door monitoring system immediately stops the print when opened. Power-loss recovery, filament detection, and the automatic backup nozzle mode ensure multi-day print jobs without production loss.

Large-format printing without compromise.

Stable, precise, industry-ready.

With a build volume of over 1050 × 1050 × 1050 mm, the D1000 Pro HS produces full-scale functional prototypes, molds, tools, and end-use parts directly in-house. The 80 °C chamber, filament drying system, and AI-assisted calibration ensure dimensional accuracy even with high-performance engineering materials. Materials such as UltraPA-CF achieve up to 80 MPa strength and 150 °C heat resistance — ideal for demanding industrial applications and validation under real-world conditions.

Creatbot D1000 Pro HS Webinar

To help you get up and running with your new 3D printer quickly, we offer you our quick start course in the form of a webinar (web-based seminar): After 120 minutes, you will understand how to use the 3D printing software.

Webinar Agenda

- Introduction to the functionality and operation of the 3D printing software

- Overview of the importance of settings

- The right settings for your perfect 3D print!

- Tips & Tricks

- Troubleshooting – Causes and solutions for common problems

Requirements

- Existing, ready-to-use PC with Windows 7, 8, or Mac OS X with full administrator rights

- Internet access

- Pre-installed and functional TeamViewer or Microsoft Teams software

The details of the appointment and the webinar software will be arranged after receiving your order.

Support and Service

- Professional consulting

- Sample print creation

- Custom packages for industrial clients

- On-site training

- Service package with free phone and email support

- Complete solution with wash station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Downloads

Technical Specifications

| Drucktechnologie | FDM/FFF |

| Bauraum | Einzel-Extrusion: 1050 x 1050 x 1050mm Doppel-Extrusion: 990 x 1000 x 1000mm |

| Anzahl der Düsen | Doppel |

| Automatisch anhebende Extruder | Ja |

| Schichtauflösung | 0.05 mm |

| Filamentdurchmesser | 1.75 mm |

| Filamentkompatibilität | PLA, ABS, ASA, PP, PETG, PC, Nylon, TPU, ABS-CF, PC-CF, PET-CF, PET-GF, UltraPA-CF, PPS-CF, etc |

| Düsendurchmesser | 0.8mm (0.3-1.0mm optional) |

| Druckdateityp | Gcode |

| Maximale Druckgeschwindigkeit | 300 mm/s |

| Flussrate | 90 mm³/s |

| Max. Düsentemperatur | 420 ℃ |

| Max. Druckbett-Temperatur | 100℃ |

| Temperatur der beheizten Kammer | 80℃ |

| Filament-Trockenraumtemperatur | 0 ℃/70 ℃ |

| Bauplatte | Flugzeugaluminiumplatten |

| Druckplatten-Nivellierung | Automatisch |

| Extruder | Intelligente Dual-Extruders |

| Automatisch anhebende Extruder | Ja |

| X-Y-Positionsgenauigkeit | 0.011 mm |

| Z-Positionsgenauigkeit | 0.0025 mm |

| Z-Achsen-Struktur | Unabhängige Vierfach-Z-Achse |

| Luftfilter | HEPA+Carbon |

| Filamenterkennung | Druck pausiert bei Filamentende |

| Firmware | Klipper - Hohe Geschwindigkeit |

| Kamerasteuerung | Fernüberwachung per Kamera und Echtzeit-Steuerung des Druckprozesses |

| Automatischer Fortdruck mit zwei Düsen | Automatischer Düsenwechsel bei Filamentende |

| Bettnivellierungstechnologie | Wirbelstrom-Nivellierung |

| XY-Offset-Technologie | HD-Kamera-Doppeldüsen-Offset |

| Z-Offset-Technologie | Doppelelektrooptischer Sensor |

| Düsenverschluss-Technologie | Doppeldüsen-Verschluss |

| Türöffnungs-Erkennung | Sicherheitstürschloss |

| Kammer-Isolierung | Interne Isolationswolle |

| Externe Luftkühlung | Ja |